After placing a countertop order, your supplier asks to schedule a templating appointment. What does this mean and why is it important?

New, upgraded countertops are a great investment for your home. As a focal point of high-traffic areas like kitchens and baths, upgraded countertops make all the difference.

The beautiful material you select, of course, is the main attention-grabbing detail, but there are other factors that impact the overall result of your new countertops – like the quality of the installation itself.

That’s why countertop templating is so important.

What is Countertop Templating?

You’ve met with your countertop supplier, picked your material and placed your order. The next step in the process is countertop templating – a key step before your supplier can actually fabricate and install your new countertops.

Countertop templating is the process of creating a template that shows the fabricator the exact measurements of your new countertop. This template gives the fabricator a precise visualization of the layout and measurements the countertop requires.

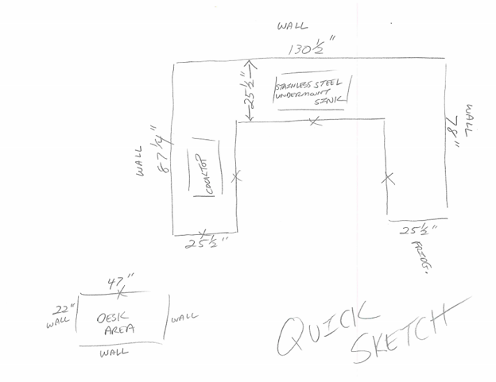

Stone countertop materials come in “slabs,” which need to be cut and shaped to fit your space appropriately. When you requested a countertop quote, you likely already worked with your countertop supplier on a dimensioned drawing. This drawing is a rough sketch of the layout of your space and total square footage, which helps you get an accurate estimate of how much material you need to fulfill your project (and the estimated cost).

Essentially, the template is a digital and much more precise version of this dimensioned drawing. At this point in the countertop process, you need more than an estimate. You need the exact measurements so the fabricator knows how to cut the slab for it to fit perfectly in your space.

Why Templating Matters

A successful countertop job starts with a successful template. This is because, the more accurate the template, the easier the fabrication and installation will be. And the more beautiful your final countertops.

Because this step requires ultimate precision, this is not something that you can do yourself. Eastern Surfaces has highly trained and skilled professionals who use computerized digital templating methods to ensure the most exacting field measurements. The best technology combined with the most skilled personnel equates to the most successful projects – time after time.

While you don’t need to worry about actually creating the template, there are some things you need to take care of before your templating appointment.

How to Prepare for Your Template

A couple of things need to happen before you can set a template date. This checklist will help you get ready for the next step in your countertop project journey:

- Prepare the property by clearing any entryways, driveways, walkways and stairs.

- Prepare the cabinets by permanently installing and leveling them.

- Prepare surfaces by placing any supports and end panels, removing backsplash if possible, and clearing off for measurements.

- Ensure all appliances and accessories are on-site or specs are available for the templater.

This list is brief, but your countertop supplier will work with you to make sure you are aware of exactly what needs to happen before your template date.

How Countertop Templating Works

Now that you’re ready for your templating, here’s what you can expect on the date of your appointment:

Step 1: Templater Arrives

The professional templater will arrive with the equipment needed to template, including a computer, tripod, laser and leveling tool.

Step 2: Equipment Set-Up

After you lead the way to the area that needs templating, the templater will check the area to be level and set up all the equipment.

Then, the templater will confirm the job details, including your countertop color, desired edge profile, backsplash and sink.

Step 3: Walls & Cabinetry Scanned

Now it’s time to start the actual templating. Using the laser, the templater will scan the walls, cabinetry faces and cabinetry ends.

Then, the templater will check the scan for accurate measurements and color code the lines per company standards.

Step 4: Pictures Taken

Next, the templater will take pictures of access and job area for the production shop to confirm that everything looks correct, or possibly determine and resolve any issues.

Step 5: Job Details Finalized & Confirmed

Then, the templater will fill in all job details on the drawing that the scans generate and create a PDF to attach in the job files. The templater reviews the drawings and other job forms with the customer and acquires signatures for approval.

Step 6: Files Sent to Fabricator’s Tech Department

Once all forms are completed, the templater will upload the drawings and pictures to the fabricator’s tech department for layout and processing.

Step 7: Materials Ready for Fabrication & Installation

With this digital, precise template and layout, the fabricator can now set up the slab for cutting. Instead of manually laying out the template on the surface of the stone, Eastern Surfaces uses CNC (computer numerical control), waterjet, sawjet and robotic equipment for peak precision shop cutting.

This process ensures perfectly cut slabs and a beautiful end result.

Experience the process yourself by scheduling an appointment to visit our showroom, and while there you can get a bird’s eye view of countertops in production. The next ones could be yours!